A project of this scale and type is certainly a first for Australia, however straw-based energy systems have a considerable track record in many countries around the world, including in Denmark, Spain, Chile and China, for instance. The technologies for energy conversion of cereal straw already exists, with experience of anaerobic digestion, gasification and combustion being readily available from a number of ‘Tier 1’ original equipment manufacturers and delivery partners around the world.

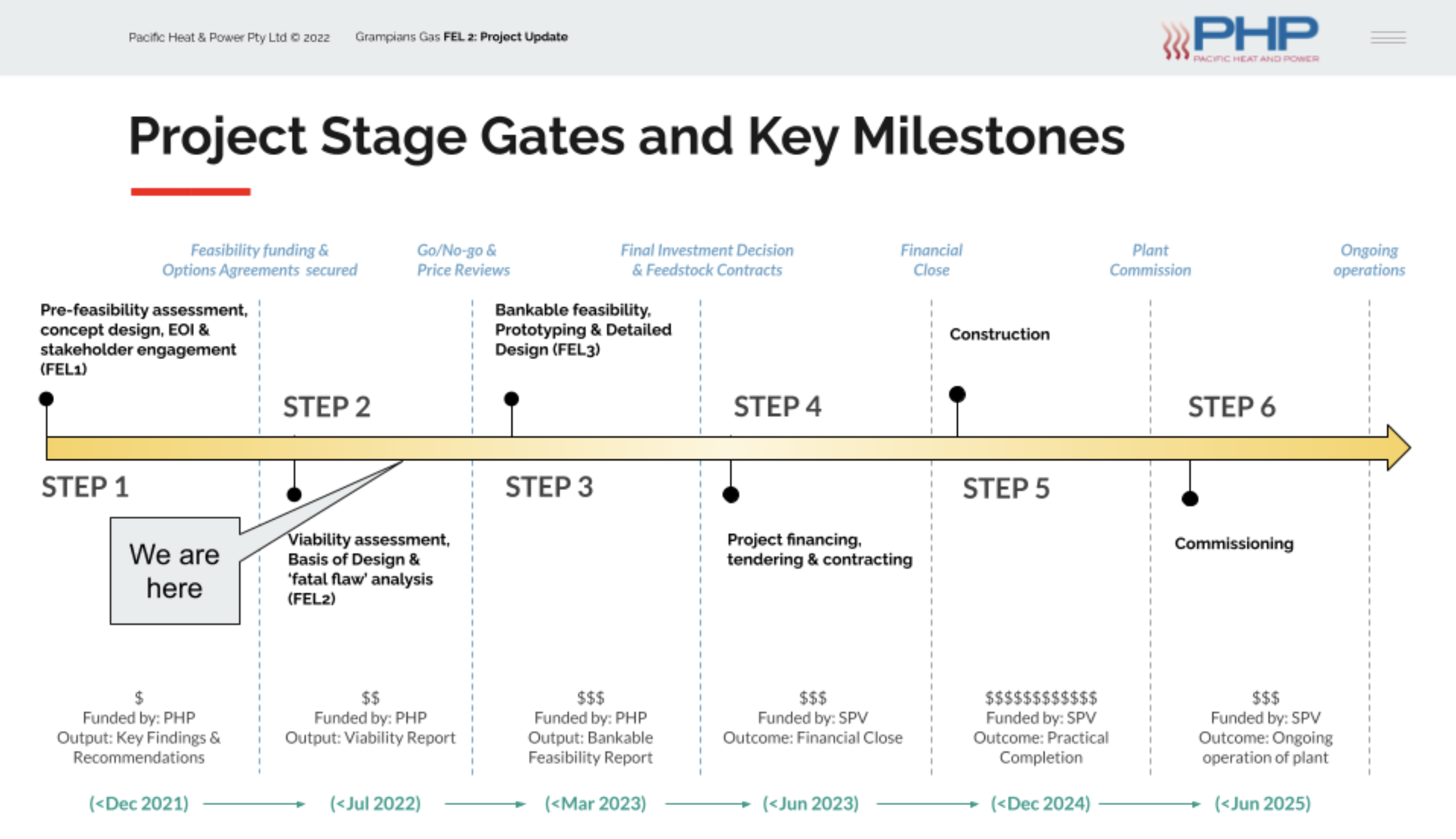

The approximate project schedule as of April 2022 looks something like this:

Recent dialogue with suppliers, construction partners and investors give us legitimate reasons to expect that the plant could in fact be delivered earlier, however we believe that the timeline above provides a realistic roadmap to work to.

Regardless of the final engineered design of the plant, all such operations are subjected to rigorous investigation as part of the statutory planning and approvals process in the State of Victoria. In Australia, the default standard is typically that such installations have to comply with the ‘Best Available Techniques’ reference documents that apply in the EU. This means that all aspects of an operation such as this are controlled in terms of inputs (e.g. fuel quality, trucking movements) and outputs (e.g. emissions to air, water, ash or noise) to international best practice standards, and will be continuously monitored for performance by the regulator (Vic EPA). The preferred plant is in fact a moderate temperature, ambient pressure system so is not expected to be dangerous when in operation. Gases of various types will be produced and handled but this is standard industrial practice and nothing out of the ordinary.

The subdivision is an important element of the project for two reasons. Firstly, it provides the opportunity for the plant to maximise its revenue base by selling energy and other co-products and services on a “behind the meter” basis. This means the plant will receive more value than it normally would by selling e.g. electricity or gas to co-located customers directly, while those customers will in turn pay less than they would for the retail price of electricity or gas, since the full costs of transmission and distribution do not apply.

Secondly, the concept is generally based on what is referred to as ‘industrial ecology’, where process inputs and outputs are exchanged between a number of co-located businesses, all which receive a benefit in terms of energy cost, carbon abatement and waste minimisation, for example. A lower cost of operating and ‘best practice’ Circular Economy precinct will attract new investment and employment to the region, thereby making these businesses more domestically and internationally competitive.

At this stage of project development, it is difficult to be definitive – until further design and costing work is done, it is challenging to settle on a final price and to do so would potentially be to the detriment of all project participants. As of April 2022, we are busy working on a final ‘Basis of Design’ document that will confirm the engineered type, preferred location and scale of the plant, as well as cementing key commercial arrangements. In parallel with this activity, we are about to enter into a negotiation period with suppliers who have previously expressed interest through the EOI process that will give us the time to collectively negotiate the terms of any offtake arrangements. At the appropriate time, should the project be deemed viable and with considerable consultation along the way, an final offer price for cereal straw supply will be put to registered suppliers with full transparency and visibility of project costs. It should be remembered that this project is being developed in the region on a true partnership basis – all we can give at this stage prior to the negotiation is a commitment to offering ‘fair value’ for all parties.

In principle, there are two scenarios for straw supply here that will affect the income you might receive, namely where (i) you do the baling yourselves (i.e. you have your own equipment), or; (ii) you use our baling contractor (we will be able to leverage a sharp price based on volume). In both instances, the project entity itself will likely be organising the haulage in partnership with local contractors to achieve ‘economies of scale’ that keep transport costs to a minimum, thereby securing the maximum supplier margin.

No – it is entirely up to you what volume as a fraction of your annual production you agree to supply to us (noting that a minimum threshold will likely need to be applied). The key point to be made here is that in order to operate our plant, we need to be able to rely on a minimum volume of fuel per annum, so will need to hold you to whatever volume you do choose to commit. Our offer does have the advantage of providing predictability of price and offtake, year after year, providing you with a stable revenue platform on which to run your business, without the need for you to be exposed to merchant or ‘spot’ pricing in the market.

The mineral content of the straw (technically referred to as the by-product known as “ash”, post-combustion) is recoverable from a thermal conversion process, while the digestion of organic materials typically yields a nutrient-dense, “digestate” that can be re-distributed to the land. Either of these by-products, and potentially biochar also (subject to final design and financial viability), have the potential to be returned to the soil via the supplier network, ensuring that both carbon and nutrient is returned and built up in the landscape, consistent with the Circular Economy orientation of the project overall. This also has the potential to offset fertiliser costs too, but the extent to which this is achievable will of course vary from farm to farm, based on land management practices and the rate of application, amongst other variables.

Much like developing a wind or solar farm, an ‘option’ (in this case, in relation to the supply of cereal straw as feedstock) is required in order to ‘buy the time’ required to ascertain whether or not the project is able to be commercially and financially supported, and thereafter, to do all of the work required to make the project happen (raise project finance, obtain relevant DA and other operating permits, build and commission the plant etc). This is a large, complex project and supply chain to establish and this takes considerable time and investment to work through. At a certain point, once contract options are ‘exercised’ at the conclusion of the proposed negotiation period, there will be financial consideration paid to those suppliers contracted, in advance of the plant being fully commissioned and supply commencing in earnest.

The short answer is yes, either directly as equity investors, or in an indirect way through a reward mechanism or similar that gives suppliers the opportunity to receive a dividend from the project ‘special purpose vehicle’ (SPV) that will be established for the purposes of owning and operating the plant. The best options are currently under investigation and will be presented in due course. At the appropriate time, an investment prospectus will be formulated and made available to registered suppliers, with a view to raising the necessary debt and equity for the project, or otherwise tabling how the proposed arrangement will work. We would recommend that you engage independent advice from your accountant or financial advisor in relation to any investment opportunity that is presented, when the time comes.

We are seeking interested cereal straw suppliers in the Ararat region (within ~100km radius). To register your interest, please follow this link and complete the Register of Interest form.